Laser marking technology has gained significant popularity in various industries due to its high precision and versatility. One area where laser marking machines have proven to be particularly useful is in marking curved surfaces. In this article, we will explore the applications of laser marking machines on common curved objects.

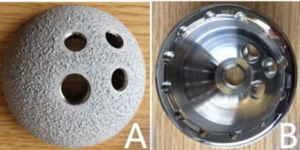

One commonly encountered curved object is the automobile wheel. Laser marking machines can effortlessly etch logos, serial numbers, or other identification marks on the surface of the wheel without causing any damage. The non-contact nature of laser marking ensures that the wheel’s structural integrity is not compromised during the marking process.

Another widely used curved object is the medical implant. Implants such as hip or knee prostheses often require precise identification marks to ensure proper tracking and patient safety. Laser marking machines offer the advantage of permanent and clear marking on these curved surfaces, allowing for easy identification and traceability.

Bottles and containers with curved surfaces are prevalent in the packaging industry. Laser marking machines are capable of marking expiration dates, barcodes, or company logos on these containers with great accuracy. The versatility of laser marking machines enables them to work on a wide range of materials, from glass to plastic, making them an ideal choice for the packaging industry.

In the field of electronics, laser marking machines are used to mark printed circuit boards (PCBs), connectors, and other components with serial numbers or barcodes. Curved surfaces on these components present a challenge for traditional marking methods, but laser marking provides a seamless solution by achieving precise and legible marks regardless of surface shape.

Furthermore, laser marking machines are also beneficial for the aerospace industry. Aircraft components often have curved surfaces that require identification marks for traceability and maintenance purposes. Laser marking provides a fast and reliable method for marking these components, ensuring accuracy and durability even in harsh environments.

In conclusion, the application of laser marking machines on common curved surfaces is extensive and diverse. From automobile wheels to medical implants, packaging containers to electronic components, the versatility and precision of laser marking technology make it an invaluable tool for various industries. As technology continues to advance, we can expect further enhancements in laser marking capabilities, opening up new possibilities for its use on curved objects.