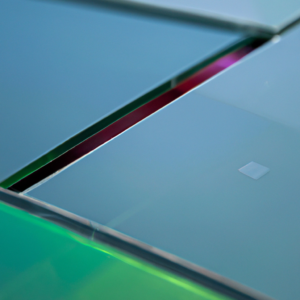

Organic glass, also known as acrylic or plexiglass, is a versatile material used in various industries for its transparency and durability. In recent years, the demand for precise markings and intricate designs on organic glass has increased. This is where laser marking machines come to the forefront, offering an efficient and precise solution for marking and cutting organic glass.

Laser marking machines utilise high-intensity laser beams to create permanent markings on the surface of organic glass. The laser beam removes a small layer of the material, resulting in a clear and precise marking. These machines can mark logos, text, serial numbers, barcodes, and even complex graphics on organic glass, enabling businesses to add a personal touch to their products or enhance branding efforts.

The advantages of using laser marking machines for organic glass are numerous. Firstly, the process is contactless, meaning there is no physical contact with the material. This eliminates concerns over damage or deformation during the marking process. Additionally, laser marking offers high precision, allowing for intricate details and fine lines to be etched onto the surface of the organic glass. The markings are also permanent and resistant to fading, ensuring longevity and durability.

Furthermore, laser cutting is another application of laser technology in the organic glass industry. Laser cutting machines utilise a highly focused laser beam to cut through the material with extreme precision. This process is ideal for creating complex shapes, patterns, or designs on organic glass. The accuracy of laser cutting ensures clean and smooth edges, eliminating the need for additional finishing processes.

The advantages of laser cutting organic glass are evident. Firstly, it provides a non-contact cutting method, reducing the risk of material damage. Secondly, laser cutting offers a high level of flexibility, allowing for intricate and personalized designs. Additionally, the process is fast and efficient, enabling businesses to increase production capabilities and meet customer demands.

In conclusion, laser marking and cutting machines have revolutionized the way organic glass is processed. These machines offer precise markings and intricate cuttings with numerous advantages, such as high precision, durability, and flexibility. As the demand for personalized and unique products increases, laser marking and cutting machines will continue to play a vital role in the organic glass industry, enabling businesses to create eye-catching and distinctive designs on their products.