CNC machining and laser cutting are two common methods used in various industries for manufacturing and fabrication purposes. While both techniques involve the use of machinery to shape materials, they differ significantly in terms of their principles, capabilities, and applications.

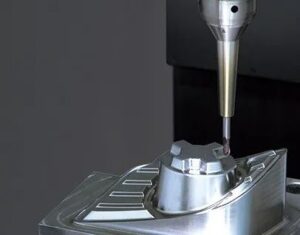

CNC (Computer Numerical Control) machining is a manufacturing process that utilises computerised controls to manipulate tools and machinery for precise and intricate cuts, drills, and machining operations. It employs various cutting tools, such as drills, lathes, routers, and mills, to shape materials like metal, wood, or plastic based on a programmed design. The CNC machine interprets the design specifications and moves the cutting tools accordingly, offering high precision and repeatability. This method is widely used in industries such as aerospace, automotive, electronics, and prototyping.

On the other hand, laser cutting is a non-contact method that utilises a high-powered laser beam to cut, etch, or shape materials. The laser beam is emitted from a laser source, then directed and focused onto the workpiece using mirrors and lenses. Laser cutting is capable of cutting through a wide range of materials, including metal, wood, glass, acrylic, and textiles, with exceptional precision and speed. It is particularly advantageous for creating complex shapes, intricate designs, and tight curves. This method finds applications in industries like signage, jewellery, medical devices, and architectural model-making.

One of the significant differences between CNC machining and laser cutting is their cutting mechanism. CNC machining relies on mechanical force from rotating cutting tools to remove material, whereas laser cutting primarily employs a high-energy laser beam to melt or vaporise the material, resulting in a clean and precise cut. This distinction makes laser cutting suitable for delicate materials that may be sensitive to mechanical stress or heat.

Another key difference lies in their flexibility and adaptability. CNC machines are often used for larger scale production runs, where multiple parts need to be manufactured consistently. They can accommodate various material types and sizes, making them suitable for mass production. On the contrary, laser cutting is highly flexible, allowing for quick design iterations and small production runs. It is particularly beneficial in rapid prototyping and customised fabrication needs.

In summary, CNC machining and laser cutting are two distinct manufacturing techniques, each with its own advantages and applications. CNC machining offers high precision and is ideal for larger production runs and diverse materials, while laser cutting excels in intricate designs, delicate materials, and rapid prototyping. Understanding the differences between these methods helps industries to choose the most suitable technique for their specific manufacturing requirements.