When it comes to product manufacturing, choosing the right method for material processing is crucial. Two widely used techniques are CNC (Computer Numerical Control) and laser cutting. So, which one should you opt for? Let’s explore the benefits and limitations of both.

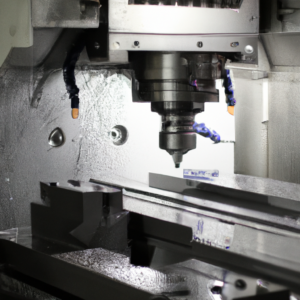

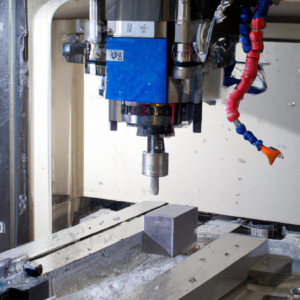

CNC cutting, also known as milling, involves the use of special computer-controlled machines to shape and cut materials. It offers several advantages. Firstly, CNC cutting can handle a wide range of materials, including metals, plastics, and wood. This versatility makes it a preferred choice for industries that require diverse material processing.

Precision is another major advantage of CNC cutting. The computer-guided machines ensure accurate cuts, allowing for complex and detailed designs. Moreover, CNC cutting machines can complete tasks quickly and efficiently, increasing productivity and reducing production time.

On the other hand, laser cutting is a non-contact method that uses laser beams to heat and melt the material, creating cuts. One significant advantage of laser cutting is its high precision. It can create intricate designs with intricate and sharp edges that are impossible to achieve with other methods. Additionally, laser cutting is known for its speed and clean cuts, eliminating the need for secondary processing.

However, laser cutting also has certain limitations. It is primarily suitable for thinner materials, as the laser beam can cause excessive heat and deformation in thicker ones. Moreover, laser cutting is generally more expensive than CNC cutting, making it less viable for budget-conscious businesses.

The choice between CNC and laser cutting ultimately depends on the specific requirements of the project. If the design requires intricate details, sharp edges, and precise cuts, laser cutting may be the optimal choice. However, if versatility, speed, and cost-effectiveness are the priorities, CNC cutting is likely more suitable.

In conclusion, both CNC and laser cutting offer unique advantages and limitations. CNC cutting stands out with its versatility and efficiency, while laser cutting excels in precision and intricate designs. Carefully assessing the project’s material, complexity, and budget will help determine the most suitable method for product manufacturing.