Laser marking machines are widely used in various industries for their high precision and efficiency. To ensure that these machines continue to function optimally, regular maintenance and care are essential. Here are some important tips for their daily upkeep and maintenance.

1. Keep the Machine Clean: Regularly clean the exterior of the machine and the marking area to remove dust, debris, and other particles. Use a soft, lint-free cloth and a mild cleaning solution to prevent any damage to the machine. Avoid using harsh chemicals or abrasive materials that can scratch or damage the surface.

2. Monitor Cooling System: Check the cooling system of the machine daily to ensure that the temperature remains within the specified range. Inspect the cooling fans, radiator, and water circulation system for any signs of blockage or malfunction. Clean or replace the cooling components if necessary to prevent overheating.

3. Verify Optical Path Integrity: The optical path of the laser marking machine is critical for its performance. Regularly inspect the optical components, including mirrors and lenses, to ensure they are clean and aligned correctly. Any misalignment or dirt on these components can lead to poor marking quality and decreased productivity.

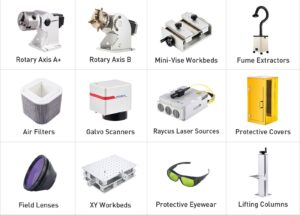

4. Check and Replace Consumables: Laser marking machines require the use of consumables like lenses or protective windows that may wear out over time. Check these components regularly for signs of damage or degradation and replace them as needed. Using worn-out consumables can compromise marking quality and may even lead to damage to the machine itself.

5. Lubrication: Some laser marking machines have moving parts that require lubrication. Follow the manufacturer’s instructions to determine the recommended lubrication schedule and use approved lubricants. Proper lubrication ensures smooth and efficient operation and prevents the parts from wearing out prematurely.

6. Software Updates: Regularly check for software updates provided by the manufacturer and install them as necessary. Software updates often include bug fixes, performance enhancements, and new features that can improve the overall functionality and reliability of the machine.

7. Safety Precautions: Always follow safety guidelines provided by the manufacturer when operating or maintaining the laser marking machine. Wear appropriate protective gear like safety glasses or gloves to protect yourself from any potential hazards.

By following these tips, you can extend the lifespan of your laser marking machine and maintain its performance. Regular maintenance not only ensures that the machine operates efficiently but also prevents costly repairs and downtime. Remember, a well-maintained machine leads to consistent, high-quality laser markings and enhances your productivity in the long run.