Wood Marking Applications of Laser Marking Machine

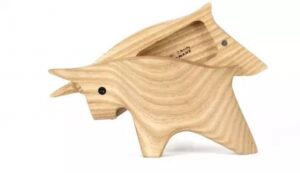

Over the years, the use of laser marking machines has gained tremendous popularity in various industries, including the wood industry. Laser marking technology offers several advantages, such as high precision, speed, and versatility, making it an ideal choice for marking wood materials. This article explores the application of laser marking machines in the wood industry and how they have revolutionized wood marking processes.The primary application of laser marking machines in the wood industry is for product branding and identification. Manufacturers can use these machines to mark logos, serial numbers, or unique codes directly onto wooden surfaces. With the ability to create detailed designs and markings, laser technology ensures a permanent and aesthetically pleasing finish. This is particularly useful for wooden furniture manufacturers and interior designers who want to leave a lasting impression on their products.Furthermore, laser marking machines are widely used for engraving designs on wooden surfaces. Whether it is intricate patterns, personalised messages, or decorative elements, laser technology offers the flexibility to engrave any desired design onto wooden surfaces with precision and accuracy. This has opened up a whole new world of possibilities for craftsmen and artists in the woodworking industry, allohem to create unique and personalised wooden products. Another significant application of laser marking machines in the wood industry is for barcode and QR code marking. Wood products, such as timber and plywood, often need to be tracked and identified throughout the supply chain. By marking barcodes or QR codes directly onto wooden surfaces, tracking become seamless, ensuring accurate inventory management and easy traceability. This greatly enhances efficiency and reduces the chances of errors in the wood industry.In addition to product branding and identification, laser marking machines are also used for surface treatment of wood materials. Manufacturers can use them to create special effects, such as weathering, distressing, or texturing, on wooden surfaces. This gives the wood a unique and artistic appearance, making it highly sought after in the market. Laser technology makes it possible to achieve these effects without compromising the integrity of the wood material.In conclusion, laser marking machines have revolutionized the wood industry by providing precise and versatile marking solutions. From product branding to surface treatment, laser technology offers tremendous benefits in terms of accuracy, speed, and creativity. With its ability to create permanent and attractive markings, laser marking machines have become an indispensable tool for wood manufacturers and craftsmen. Embracing this technology allows the wood industry to stay ahead in terms of quality, efficiency, and customer satisfaction.